SLURRY FOX SFP 3L

The mobile solution for your day to day operation

Portability:The Slurryfox SFP 3L is designed for sawing and drilling contractors who require portability on the jobsite for water recycling and reuse.

One-Man operation: The filter press incorporates many of the same components as the Slurryfox SFP 8L but is built so that it can be handled by one person.

360° closed-loop concept: The SFP 3L is the ideal solution for slurry water processing at the source, or on the truck, utilizing the “360°“ closed-loop concept for water recycling.

Powered by a single-phase air compressor, the new SFP 3L is the most efficient solution for concrete slurry processing. Separation of solids and water allows for compliant disposal.

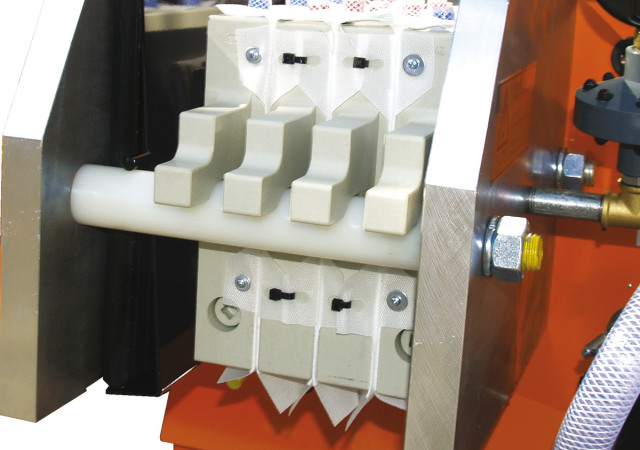

Consisting of three elements – container, chamber filter press and control unit – the SFP 3L is the most compact, mobile, simple to operate and efficient filter press on the market.

The new patented airbladder technology allows for a lightweight and compact design of the SFP 3L – weighs just 79 kg (174 lbs) for easy transport.

Specifications

| Operating: | 100% pneumatic | |

| Air required: | 250 l / 8 bar (66 gal / 116 psi) | |

| Recycling Capacity | 400 – 600 l/Std (100-160 gal/hour) | |

| Filtervolume (solids) | 2,4 liter (0,7 gal) | |

| Dimensions (LxWxH) | 600×630×950 mm (24”×25”×38”) | |

| Weight | ca. 79 kg (approx. 174 lbs) | |

| Order number | 0284 000 2000 |

Recommended Air Compressor

| Air compressor | GV22-11 or (Ingersoll Rand P1.5IU-A9) |

| Motor | Single Phase 230 V, 2,2 kW (115 V- 1,5 kW) |

| Capacity | 340 l/min (89 gal/min) |

| Airpressure | 8 bar (116 psi) |

| Compressor Unit | 2 cylinder – 1.450 rpm |

| Order number | 0295 150 0115 |